ROLL-CAGE & CHASSIS

Your performance vehicle deserves a foundation built to match the ambition of its engine.

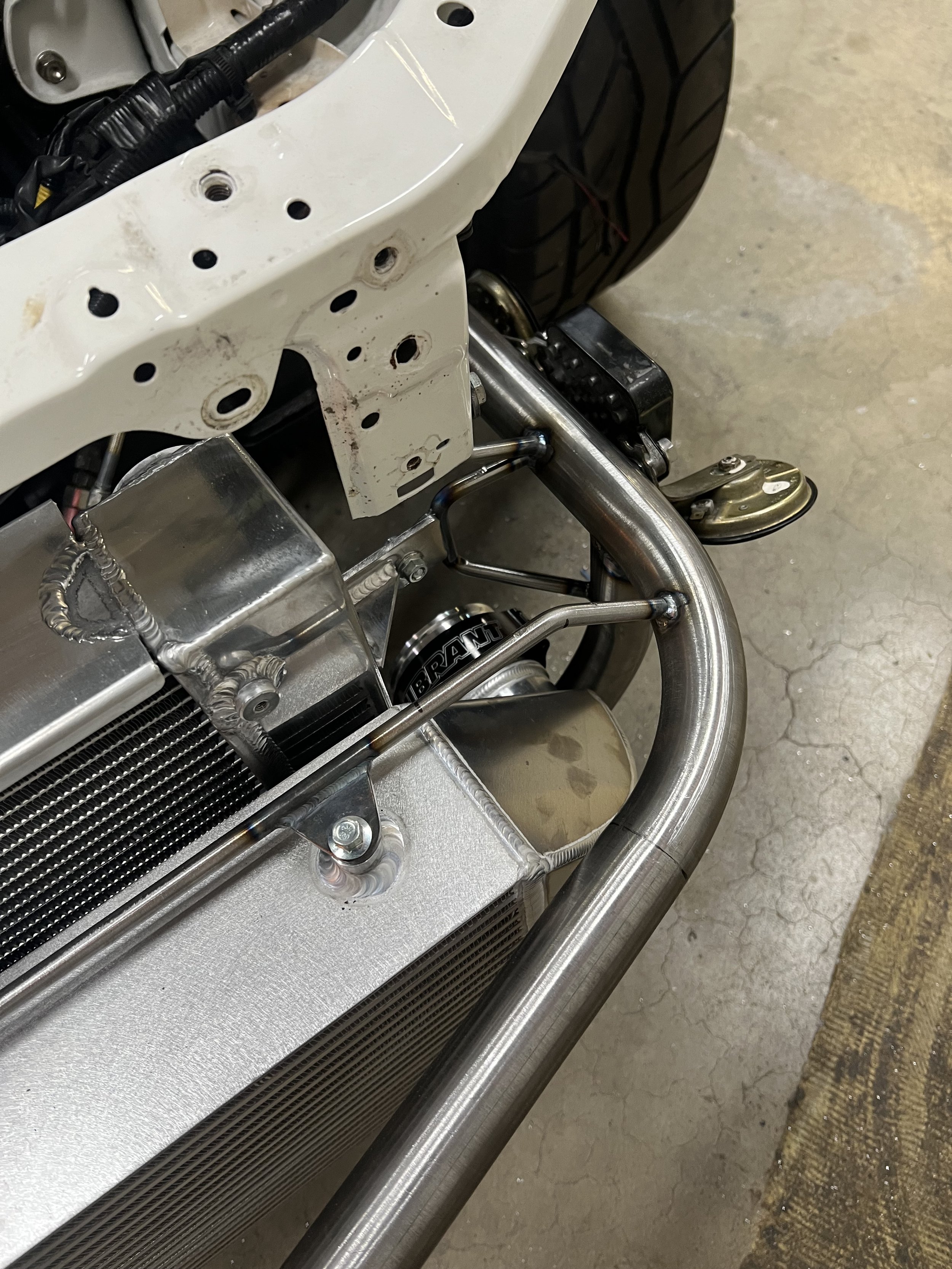

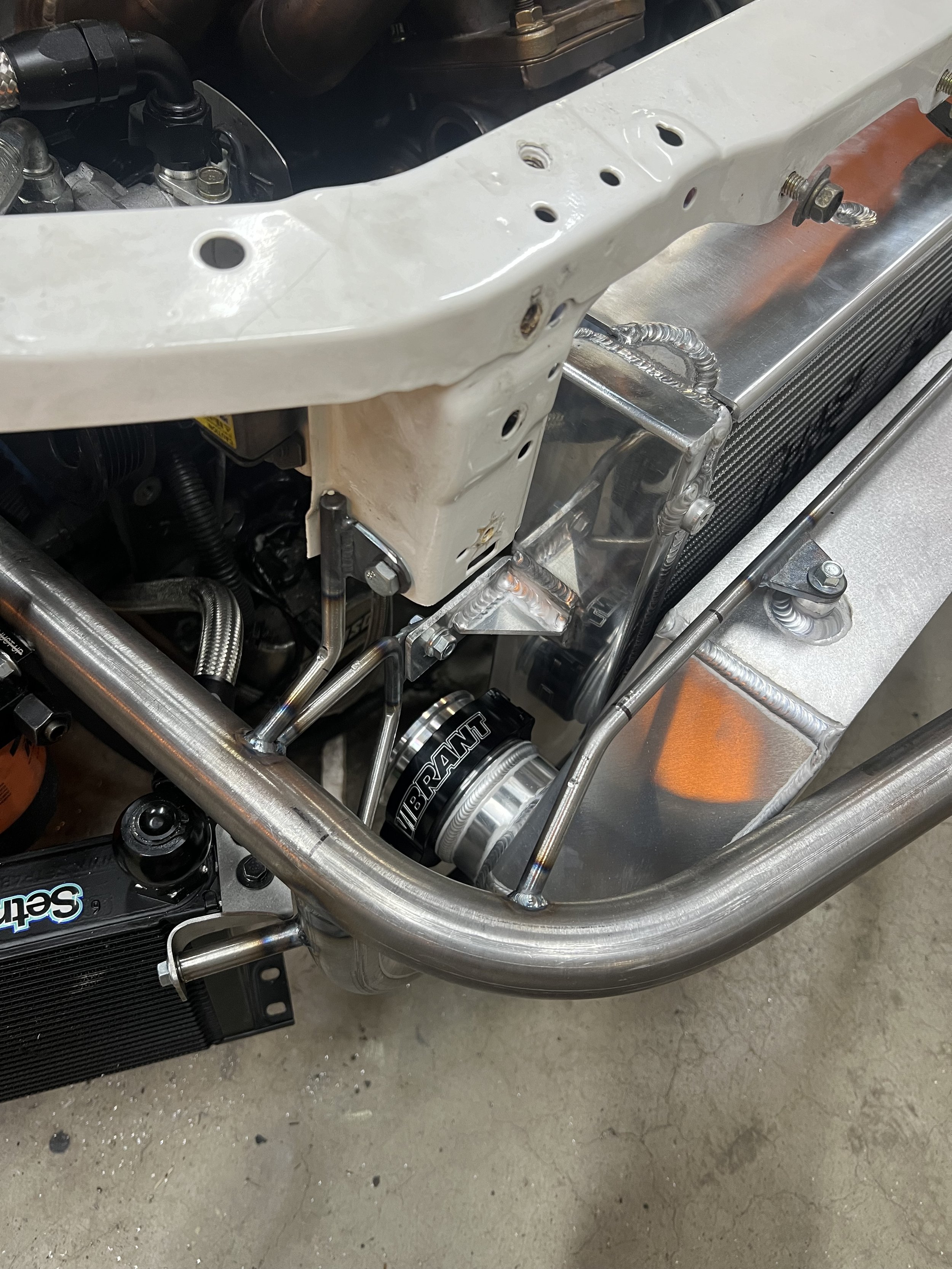

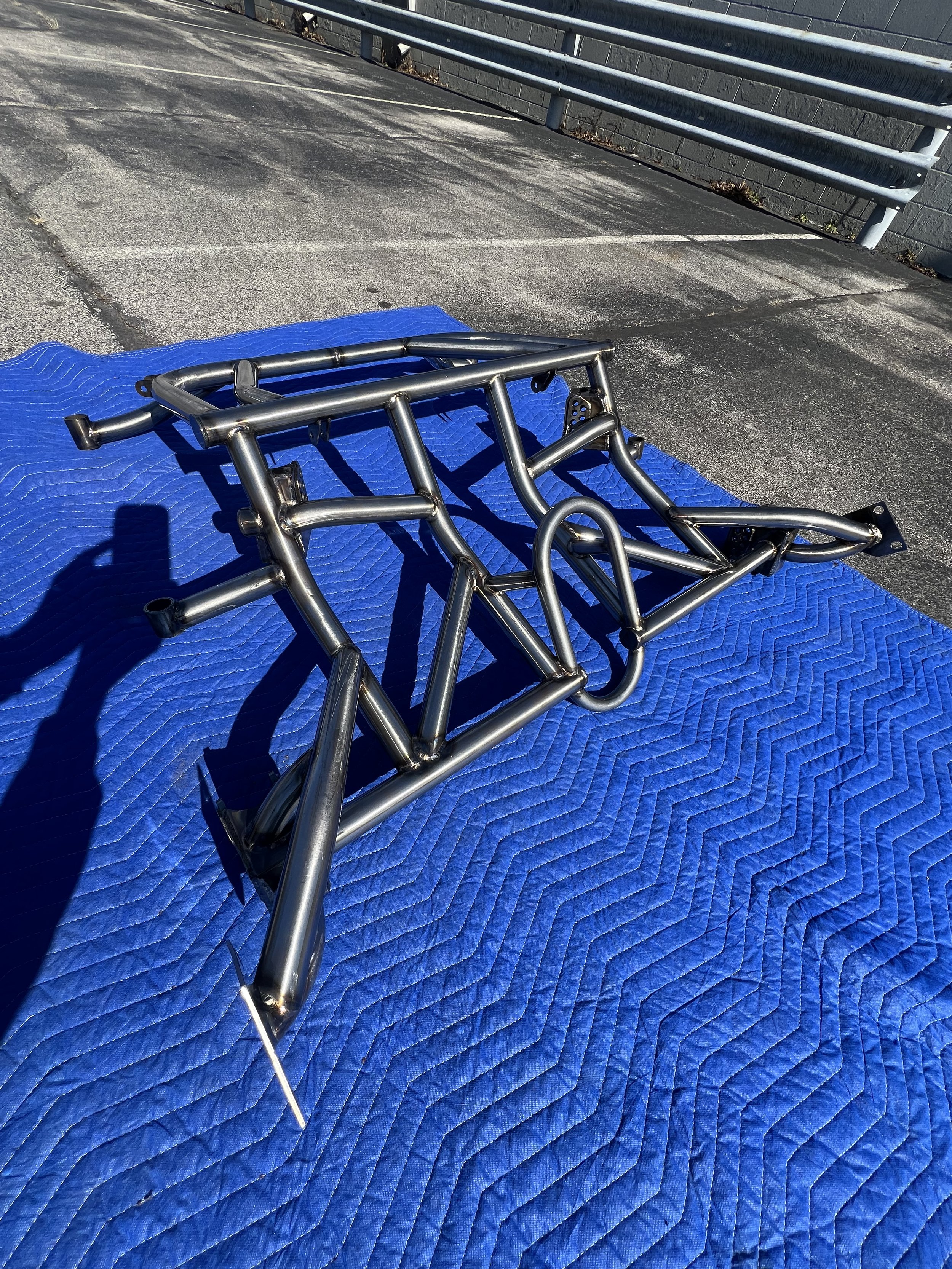

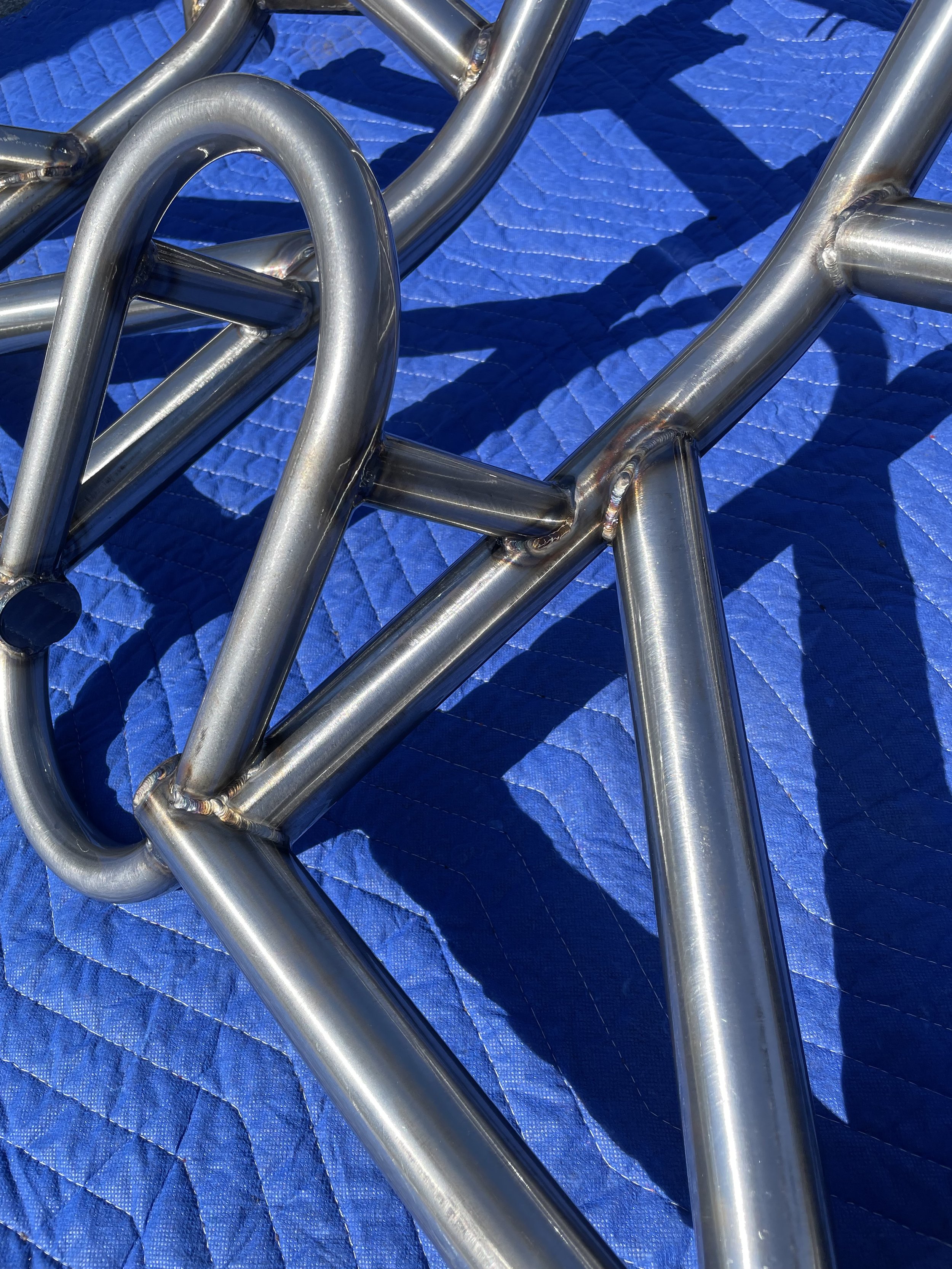

At ScroggsFab we specialize in roll‐cages, sub-frames, bracing, and full chassis fabrication, handling everything from NHRA drag layouts to drift/circuit competition rigs.

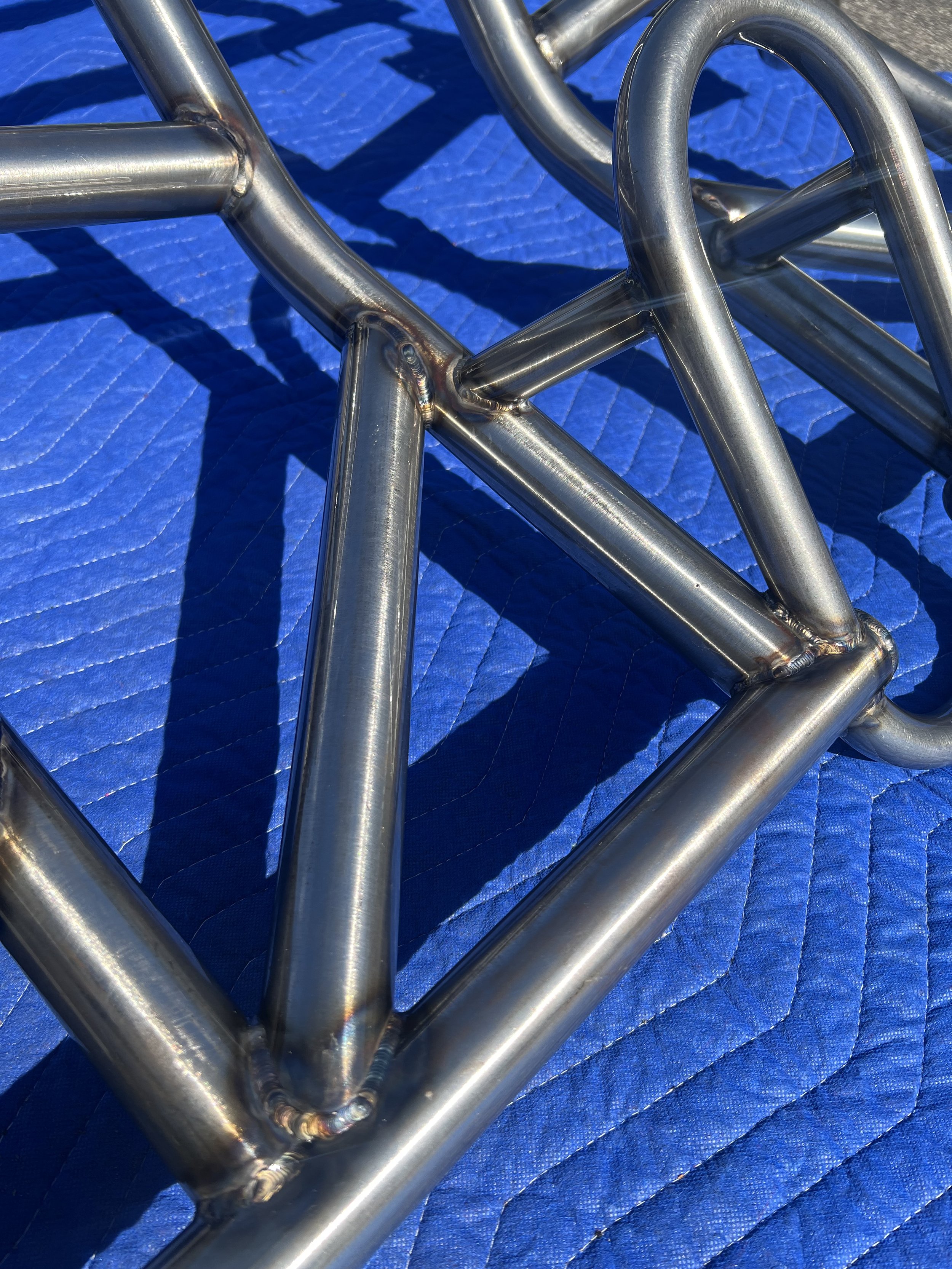

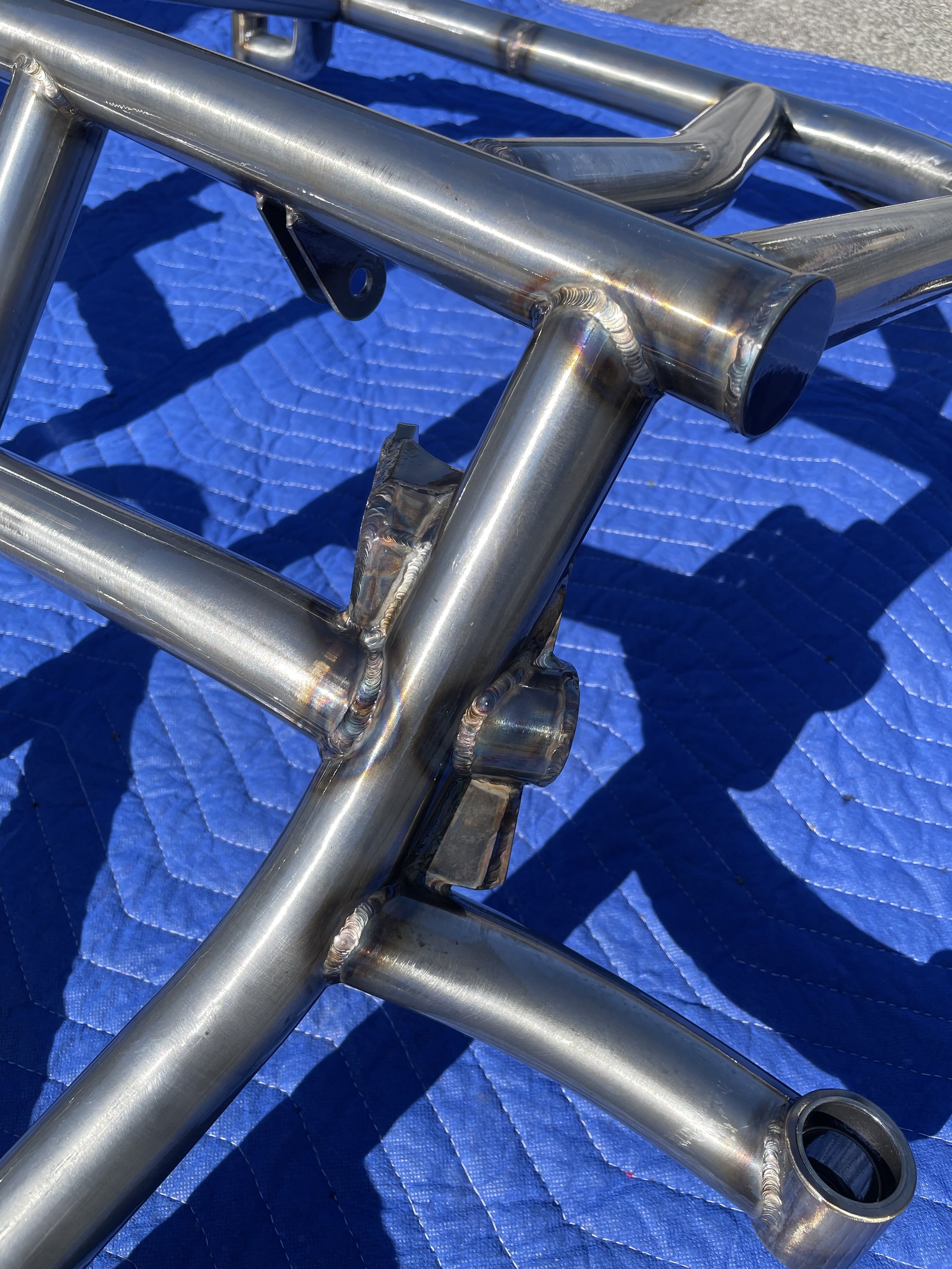

We use DOM or chromoly tubing (based on class requirements) and plan each cage using approved design drawings when applicable. All mounting points are jigged, laser‐measured and then tack‐welded prior to final welding to maintain perfect geometry and alignment. Our welders are certified and use inert‐gas shielded MIG or TIG wires appropriate for material and thickness. After full welding, all seams are inspected, ground smooth and ready for final finish (powder-coat or bare as required).

Beyond cage fabrication, we offer custom sub-frames, rear cradle conversions, integrated harness mounts, parachute mounts (drag use), skid plates and suspension mounting points. Every detail is laid out in advance during a consultation—seat position, door bar clearance, harness bar height, fire suppression system boots etc.

Our priority is safety, alignment and serviceability. Every bracket we supply is built in-house, and we always account for future service (fuel system leaks, shock access, wiring runs). Whether you're prepping for 4-second passes at the dragstrip or open-track excursions, we build your chassis with one goal: endure, perform, win.

Ready to get started? Schedule your build consultation or submit your project details—we’ll review the scope, timeline and materials list, and you’ll get a transparent plan to move forward.